|

This was my arrangement since purchase and rarely had problems with connections

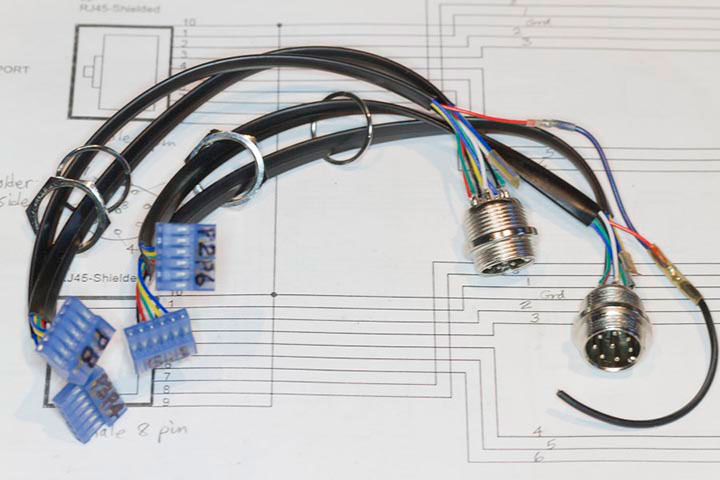

CGE Pier Motor Control Board connectors soldered to 8 pin connectors

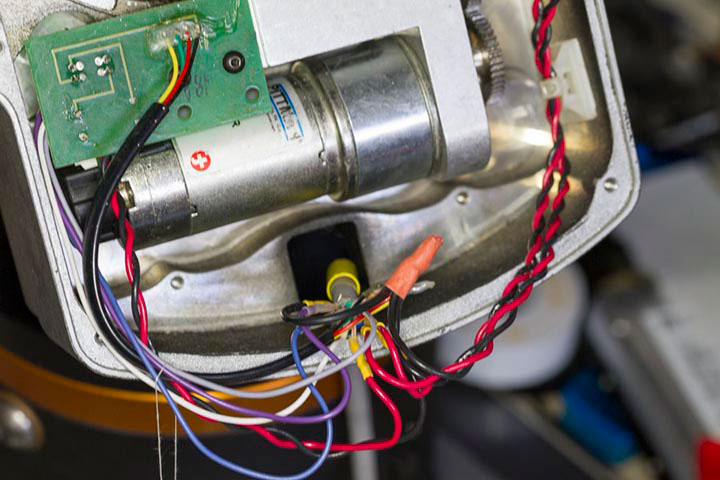

Cable, with RTV silicone through RJ45 hole, is soldered to existing CGE DEC motor box wiring

The CGE assembly weighs about 45 pounds and is almost never disassembled. A Dremel grinding wheel on a drill press cut enough aluminum to allow connections to seat flush in existing ports. Hand moldable epoxy and paint finished it up. Modifications costs $12. Gary Bennett inspired the mod.

5 pound counterweight made with barbell weight, 1 1/2” copper pipe, 1/4-20 stainless steel insert, hand moldable and steel epoxies, aluminum blind slat, and C14 lock screw. Usable on both mounts.

Finder adapter made from aluminum channel, fiberglass circuit board, moldable epoxy, and screws secured to spare 10x40 C11 finder. This provides good registration in the Meade shoe on the Explore 127mm f7.5 carbon fiber tube.

1/2 x 3 x 7.5” 6061-T6 aluminum D dovetail with M6x1.0 x 20mm Flat Head allen screw on the ES127 tube rings.

The ragged appearance is epoxy filler and aluminum foil to provide a flat surface to mate with the top of the saddle.

Fabricating tripod feet with red oak and M20x2.0 x 60mm bolts and nuts

CGE Pro tripod leg on a Celestron Vibration Suppression Pad.

Stainless steel pipe clamp keeps leg brace from riding up the leg.

M7x1.0 x 55mm socket head cap screws and 7/16" aluminum tubing allows easy disassembly of the CGE Pro DEC head. Each component weight is equivalent to the Astro-Physics AP1200 mount. The screws and allen wrench have heatshrink tubing to locate in the dark.

Tools for CGE Pro knobs and clutches - Heat gun shaped PVC with washer from undercounter water filter cartridge.

Anderson Powerpole connectors on a Costco Deep Cycle Marine battery. Each output is fused.

|